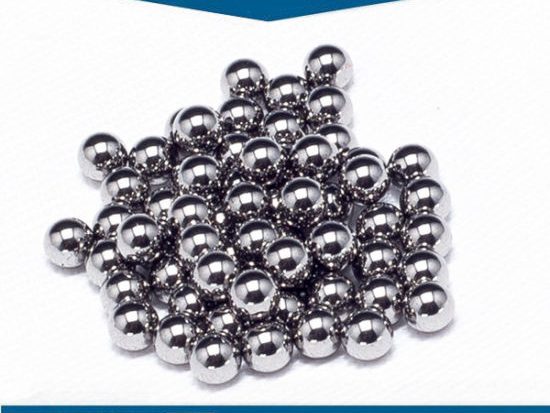

Steel balls are spherical components that are being used in several industries. They are used because of their rolling mechanism. Steel balls are mostly used mostly because of their rotary motion, therefore, you will find them in wheels, bearings and a plenty of other tools and equipment.

Steel balls are used extensively for making different types of grinding machines. In fact, it is even used to make certain kind of toys and a plenty of other things. Many steel balls manufacturers from India make a wide range of steel balls which are perfect for different machinery and tools. Diverse applications of steel balls lead to very high demand of the balls. In this article, we will explore the process of making steel balls.

The Process of Making Steel Balls

The manufacturing process of steel balls is streamlined. Steel balls manufacturers from India uses a wide range of different methods to make high quality steel balls for the industries. Most of the bearing balls are made using steel wires. Sometimes, even rods are used to manufacture steel balls.

The first step of making steel balls is to cut the wire in different pieces, which are known as slugs. The quantity of the material for the slug is to some extent greater than the finished ball. Extra material is required to make the perfect steel ball for the industries. However, at a later stage, the entire extra slug is removed. It is mostly removed at a later stage, after subsequent machining steps are performed.

Although, till this time, the slug or material is still not strong enough. It needs to be hardened more. At this time, the material is a bit malleable. Therefore, the slug or the extra material is used to perfectly shape the ball. If the steel balls need to have the ideal spherical shape, a certain degree of manufacturing steps need to be followed. Steel balls manufacturers from India makes sure that they follow the right process to form the perfectly shaped steel balls.

Steel balls manufacturers also keep these things in mind:

- Quality

Most of the steel balls manufacturers make sure that the quality of the steel balls is excellent. To ensure that the quality is as expected, steel ball manufacturers would have to use the best raw material. Therefore, most of the steel ball manufacturers have been partnering with the topnotch vendors to procure the best quality raw material for the steel balls. Only top quality steel, wires, rod etc. are used to make highly efficient and strong steel balls. Also, most of the good manufacturers have a quality team that keeps an eye on all the manufacturing process just to make sure that the quality of the steel balls is up to the mark.

- Modern infrastructure and cutting-edge technology

Several Steel balls manufacturers from India use modern infrastructure and cutting-edge technology to manufacture high quality steel balls for the market. Good steel balls manufacturers get the latest machineries as well as the equipment to automate the manufacturing process and to deliver the best quality products for the industry.

The process of making steel balls needs a bit of effort. Therefore, it is important for the manufacturers to keep upgrading and evolving to make the best quality steel balls. The complete process of making steel balls could possibility be optimized and automated with time as well. It is just that the manufacturers have to stay up to date with the latest happenings in the world of steel ball manufacturing.

You may like to read on Machine Vision-based Surface Inspection System for Precision Steel Balls